We accompany our clients throughout the entire process, from the birth of the idea to the delivery of the pieces to their destination.

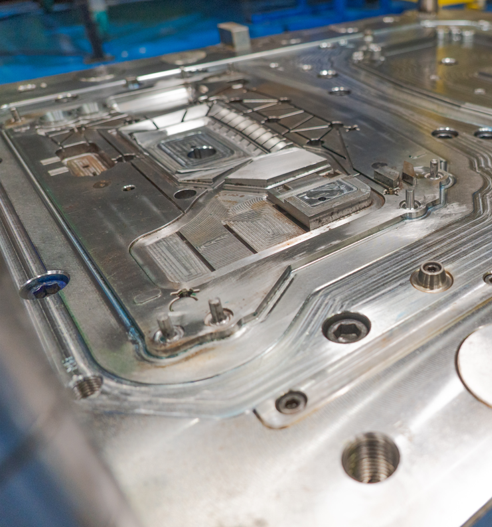

We have state-of-the-art machines for the injection of plastic parts of all types, from 35 to 650Tn, specializing in 2K multicomponent injection

Capacity of Production